Casting and Forging

The casting and forging industry stands as one of the primary sectors where trillions worth of materials are left uncoded annually, attributed to diverse heavy processes and operations.

In the casting and forging industry, high scrap rates and scrap-related costs are persistent challenges, often stemming from issues like process variability, insufficient traceability, and undetected quality defects. CDOT addresses these issues with its highly durable, AI-powered 2D code, which ensures end-to-end traceability even under the most extreme industrial conditions. By enabling real-time monitoring of process parameters and capturing precise data for each component throughout production, CDOT allows manufacturers to identify and address quality deviations early. This not only reduces scrap but also minimizes rework costs, enhances operational efficiency, and ensures consistent quality control, making it a transformative solution for tackling scrap-related inefficiencies.

Processes

Aluminum / Magnesium high-pressure die-casting (HPDC)

Value Chain

Casting

Heat treatment

E-coating, convertion, powder coating

Where CDOT code is applied

Appilied to casted part at up to 700°C / 1292°F part temperature

Before heat treatment

Before coating

CDOT code readability

Reads on casted part at 700°C / 1292°F part temperature

Reads on part heat treated up to 700°C / 1292°F

Reads on part through 700 μm of coating

Iron / Steel Sand Casting

Value Chain

Sand Mold

Where CDOT code is applied

Unique CDOT codes are marked onto sand molds, then the hot ore is transferred into the marked cavities

CDOT code readability

Reads on casted part taken from sand mold

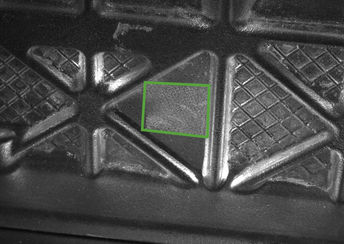

Aluminum / Magnesium high-pressure die-casting

Aluminum / Magnesium high-pressure die-casting

Aluminum low-pressure die-casting (LPDC)

Value Chain

Casting

Heat treatment

Where CDOT code is applied

Appilied to casted part at up to 700°C / 1292°F part temperature

Appilied on part before heat treatment

CDOT code readability

Reads on casted part at 700°C / 1292°F part temperature

Reads on part heat treated up to 700°C / 1292°F

Benefits

Improved Data Association

Unique identification

Each CDOT code is unique and permanently linked to a specific physical part, allowing for seamless tracking and identification throughout casting production, ready-to-mount stage, and lifecycle.

Reliable data capture

When CDOT codes get damaged or obscured during the stages of casting manufacturing, the link between the physical part and its digital twin is not broken. CDOT codes are durable to ensure data capture throughout the casting process, maintaining the crucial association for real-time data exchange and synchronization.

Enhanced Data Analysis

Complete data sets

Incomplete data due to damaged or destroyed codes hinders comprehensive analysis. Durable CDOT codes guarantee complete data sets from the stages of casting manufacturing, enabling in-depth analysis of performance and quality.

Connected traceability

By scanning the CDOT codes, you can access detailed information about the part's origin, material composition, manufacturing process values, quality checks, and current location. This improves transparency between customers and casting manufacturers and simplifies supply chain management.